Tire Pressures

Consider the following:

A tire produces grip through two primary methods:

- The mechanical interlock between the rubber in the tread of the tire and the irregularities in the road surface; and

- Molecular adhesion between the sticky/tacky rubber compound in the tread, and the road surface.

Thus, we would expect the tire to produce more grip the harder it is pressed into the road surface, by:

- Forcing the tread rubber into increasingly smaller voids in the road surface; and

- The increase in molecular adhesion corresponding to the increase in contact surface area as the rubber is forced into more voids in the surface.

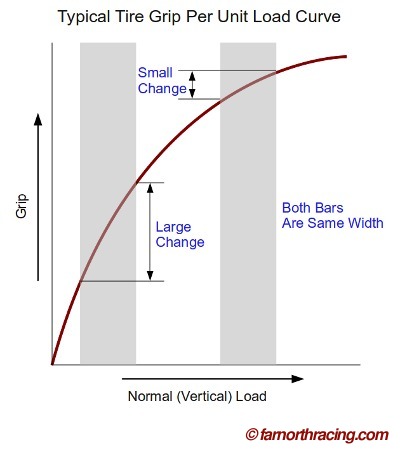

And this is exactly what happens. The increase in grip is not linear with the increase in normal load, as you get increasingly smaller voids to fill with rubber the more you load the tire (it's actually a fractal function). This is called "load sensitivity" and is a major influence on handling.

However, the tread rubber is not backed up by a solid, incompressible block: it is supported by the air pressure in the tire. As you squish down on the tire, the force to overcome the air pressure must be higher than the force to squish the rubber into the road surface, otherwise the tire will deform rather than fill more voids in the road surface and gain more grip.

This in turn implies that the higher the pressure inside the tire, the more grip it can provide.

But there is a catch - the air pressure inside the tire presses evenly along all interior surfaces of the tire's carcass. It is trying to force the tire into a torus shape. But the tire is constructed to form more of a cylinder than a torus (the tread surface is flat in cross section, not round) so the carcass itself must resist this force trying to change it from a cylinder to a torus.

If the pressure gets high enough such that the carcass cannot maintain its shape across the cross section of the tread area, the edges of the tread will pull up from the road surface and lose contact pressure - perhaps, in extreme enough cases, to pull completely off the road itself.

In any case, the tire produces maximum grip when the rubber across the tread face is equally loaded, meaning equally supported. So when the internal air pressure starts to deform the tire towards toroidal shape, the tire will start to lose grip.

From all this, we can assume the following:

- A tire will gain grip with increasing tire pressure until the internal pressure overcomes the strength of the carcass portions that keep the tire cylindrical, at which point the tire will start losing grip;

- A tire with a fairly rigid construction (a DOT-approved tire) will want more total pressure than a tire with a floppy construction (race slick);

- A wide tire (with a large unsupported beam section across the tread section area) will stand less total pressure than a narrow tire; and

- A soft tire will need less pressure than a hard tire.

And this is pretty much what is observed in the wild. A wide, floppy, soft, and sticky race slick might use 15 PSI, but a narrow, stiff, hard, and smooth OEM street tire might use 55 PSI.

So then, what is the ideal tire pressure?

The answer is "it depends" and the primary variable is the tire construction. Each tire family is going to respond to pressure differently, because the carcass construction is going to vary so much. Within a tire family, we can expect that the wider the tire, the lower the pressure, and usually, the hotter the tire (softer) the less pressure it will need... but none of this gives us absolutes.

Determining the ideal pressure is the realm of testing, I'm afraid - although skidpad testing (with the help of an accelerometer) makes it a lot simpler:

- Start with the tires cold and at a set starting pressure;

- Do a few hard turns around the skidpad;

- Record peak G, end temperatures, and resultant pressure;

- Let the tires completely cool down, increase pressure by 4 PSI, and repeat;

- When grip starts to drop, decrease pressure by 2 PSI, and repeat;

- Add 1 PSI, and repeat; and finally

- Drop 2 PSI, and repeat.

And now you know where the peak grip pressure is for that surface and that temperature - which is almost certainly NOT the peak grip pressure for all temperatures and surfaces, but it at least gets you in the ballpark.

The important part is to let the tires cool off between skidpad tests - which can be tedious. Remember: most of your runs will start off with the tires at least partially cooled off; almost never do you get to start a run with the tires at full operating temperature.

From that point on, take notes during other testing or during events. If you balance the car during an event by changing the tire pressure, make note of the change, and if the change increased or decreased grip on that end of the car.

My goal was to find the pressure that produced maximum grip on the front end of the car (AWDs understeering by nature) and then balance the car by tuning the rear pressures. A similar strategy is probably good for FWD cars. RWD cars probably want to maximise rear grip and tune with the fronts.

A few more points:

- I never bothered bleeding pressure out of hot tires; instead, I set cold pressures based on surface and ambient temperature and left the hot pressures to themselves. If I changed tire pressure during the event, it was an attempt to change handling balance, not to keep the tire constant. The reasoning is fairly simple: it's one less thing to worry about on the grid. Most events, I set pressures on day one, and then never touched the car again.

- The use of nitrogen instead of compressed air does indeed help reduce the amount of pressure change due to water vapour content with temperature change. Lugging a nitrogen bottle around in grid, however, is a pain in the ass. It's bad enough having to carry the mini bottle to service shocks without needing a full sized bottle to service tires. So instead, I mounted and filled with nitrogen and did any at-event service with the compressor off the Hoosier truck - which, if you look closely at Hoosier Tom's compressor, has a big-ass air dryer on it. I also filled my portable bottle from his dry-air compressor. At one point, I considered mounting a dryer to my portable bottle, but never got around to it.

Tires

Tires