One of the big problems with the 2G DSM is that the shock fitment it uses is specific to the 2G and no other vehicle. Accordingly, you don't have much choice when it comes to sourcing off-the-shelf aftermarket shocks. You either build your own custom stuff or you buy Koni Yellows.

Koni Yellows aren't a bad shock but Koni designs them to work with the OEM springs and the OEM upper mount, which just doesn't cut it from a performance perspective.

What you need is a coilover - with a proper coaxial upper spring hat.

Lots of people make reasonable coilover sleeves for Konis, but nobody makes a proper spherical bearing upper shock mount.

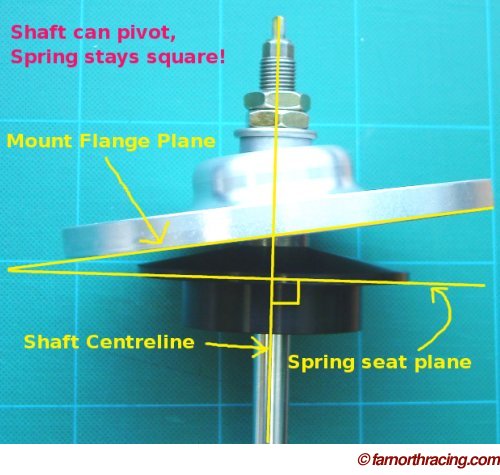

There is a commonly available aftermarket upper mount, but the spring rests directly on the underside of the mount plate, and that is a HUGE no-no. The spring needs to be able to pivot to be able to remain coaxial to the shock shaft without bending, like so:

I cannot possibly emphasise this enough: the 2G DSM front suspension pivots several degrees back and forth just by turning the steering wheel lock-to-lock. The Audi-style double-lower-balljoint "virtual steering pivot" front suspension is designed to swing the shock around. Any resistance to the shock rod pivoting will either bend the shock rod or buckle the mount. If the spring is not kept coaxial to the shock rod and also allowed to pivot, the spring will bend and bow and the spring rate developed will vary unpredictably.

This is so important that it actually takes precedence over the shock itself. Moving from Konis (reasonably valving) using the POS Ground Control upper mounts, to first generation ShockTeks (horrible valving) but with proper coaxial mounts actually made the car quite a bit faster. At the time, this was misinterpreted as the ShockTek being a better shock. Later, once I started dynoing shocks and discovered how far out to lunch the ShockTek's valving was, and the true importance of the upper mount became clear.

Properly valved Far North Racing custom Bilsteins (ShockTek had gone under and I was building my own stuff by then) were even better. But if you can't lay hands on a set, or if you're not up for the fabrication required to mate a Bilstein body to a 2G (especially in front - rears are far easier to do) the Koni-based solution is actually pretty good from an absolute performance standpoint, and is great from a "bang for the buck" perspective.

Because DSMers are by definition and inclination CHEAP, let me spell it out for you. The Koni Yellow based solution is the cheapest "real suspension" you can build for a 2G DSM.

So then, here is how you build a proper Koni based 2G shock setup:

You need:

- A set of Koni Yellow shocks. They will need to be dynoed, and they need additional snap ring grooves cut into them (Koni North America should be able to do this, or any decent machine shop)

The grooving operation is simply chucking the shock up in a lathe, and hitting it with a grooving tool (usually a parting blade of the right thickness) It is not rocket science and is really very easy - the only "hard" part is finding a lathe big enough (a 4" swing mini-lathe from Harbour Freight won't do it) It pays to call a few different machine shops and ask around; a lot of the bigger shops will price small jobs prohibitively because they want to discourage looky-loos, and because setup for "small jobs" has a way of getting out of hand and eating the profit margin. Small shops are more willing to take on small jobs.

If you really cannot find a way to get the shocks grooved, you can substitute the Ground Control coilover sleeves for the Koni sleeves, as the GC sleeves are correctly sized to fit on the OTS Koni perch snap rings. DON'T buy their springs, and DON'T buy their upper hat. You'll have to substitute 2.5" OD springs for the 2.25" OD springs called out below, you'll need 2.5" OD bearings (NTA-4052, races TRA-4052), and you'll need adaptor sleeves to fit the spring to the top hat (Koni part 15.29.04.003.0, 1 per shock).

- 4 x Hypercoil springs, in 2.25" x 8". Use the Suspension Dynamics Worksheet to work out your rates.

- 4 x Hypercoil 2.25" "helper springs". These are flat springs with minimal rate; they are designed to collapse as soon as any weight is placed on them. They keep the main springs from rattling around.

- 4 x 2.25 ID Torrington bearings, with races (you need 8 x races) Bearing part number is Timkin NTA-3648 (1 per pack) Races Timkin TRA-3648 (1 per pack)

- 4 x Koni coilover sleeves with low-profile hats, part number 80.0000.1. If you are going the Ground Control sleeve, 2.5" OD spring route, you need 4 x Koni 15.29.04.003.0 (spring adaptors) and 4 x Koni 80.0000.0007 (25mm upper spring hats)

- 4 x Aurora PNB-12T spherical bearings

DO NOT SKIMP ON THE BEARINGS! When you use spherical bearings loaded axially instead of radially, the load capacity goes way, way down and cheap bearings cannot handle the load or the wear. The PNB-12T bearing is strong enough for use axially and it is made to last a long time. If you cheap-DSMer the bearing, you run the very real risk of the bearing loosening up and eventually punching through. Use the correct part for the job!

- 4 x Upper mount plates. You are going to have to have these made yourself.

Here is the drawing - 4 x Upper Standoff. You are going to have to have these made yourself.

Here is the drawing - 4 x Lower Standoff. You are going to have to have these made yourself.

Here is the drawing - 4 x inside snap ring part HO-143

- 10 x M10x1.5 socket head screws, with nuts and washers (3 each on the front, 2 each on the rear) You can substitute button head screws if you are nervous about contact between the screw heads and the spring hat

- Access to a small hydraulic press for pressing in the bearings.

The spherical bearing is press-fit into the upper mount plate and then retained with the snap ring. Be careful pressing it in, and be sure to use lots of lube, because if it gets cocked in the bore, it'll ruin the upper plate - The hard-anodized finish called out on the upper mount plates really helps here. Slide the coilover sleeve over the shock, then add the Torrington bearing (race, bearing, race), the helper spring, and the main spring. The spring hat fits over the top of the spring, then the lower standoff, the upper mount plate, and finally the upper standoff.

HERE IS THE DEAL: - I placed this design on the website so that people can have this setup made and drive on a real set of shocks, not crap like KW, BC, Tien etc. There are, however, some conditions:

- No DSM vendor is allowed to make and sell this setup EXCEPT Magnus Motorsports. PERIOD. It is OK if random shops sell you the shocks

(although you really should be buying them from someplace that will provide dyno plots) but it is EXPLICITLY NOT OK for ANY shop to duplicate and sell this setup.

RRE has an upper mount plate setup that is very similar to mine. They developed it independently and concurrently to mine, so I have no claim on the design and no beef with them selling it as long as it is their design. Handing RRE my drawings and asking them to duplicate it is not kosher at all unless they sell every single bit to you at cost.

- Private DSMers may organize "group buys" It is cheaper to have machining and anodizing done in large batches, and Konis are best bought in bulk so they can be dyno matched. Accordingly, it is allowed for private individuals to organize "group buys" and batch jobs. But you may not charge any profits or fees over and beyond what it costs to make and ship them. No "handling fees" or "finder's fees" or anything like that and you must provide accounting info to all members of the group buy, including copies of invoices.

- I put a lot of work into developing this setup and I answer a LOT of questions. It takes time to keep the websites up to date, it takes money to pay for bandwidth. If you get some use out of this site, I would very much appreciate it if you visit a few of our advertiser's sites or use the PayPal Donate button below to show your support and keep future updates flowing.

Learned Somthing?

Help support autox.dsm.org!